China wholesale Dough Cutter And Rounder - Dough Divider and Rounder YQ-605 – Yuyou

China wholesale Dough Cutter And Rounder - Dough Divider and Rounder YQ-605 – Yuyou Detail:

Detail

The machine is suitable to produce dough balls in various weight continuously.And it divide dough into small dough balls in same weight.It combines the functions of traditional dividing machine and rounding machine,and saves producing space.The cone is replacable.And it can also be customized.There are 2 sizes of each roller barrel.It can be transferred between 2 sizes by pressing button.The machine is covered with Stainless steel surrounding panels,and the inner structure is easy to dismantle and assemble.And it is also simple to clean and maintain.It is completely one-man operated machine.So it can also save labor cost for you. Till now,very few factory can manufacture dough divider and rounder,2 function in 1.So we take great advantage in developing technology,producing capacity and competitive price in the market.And there are 3 pocket and 5 pocket version.Clients can choose according to their production requirement.

Remark:As the dough ball weight is 25-100g,we have to make initial dough dividing by auxiliary dividing facility.And the dough balls will be fed by conveyor to the dough divider and rounder YQ-605.

Specification

|

Model No. |

YQ-605 |

|

Power |

1.65kw |

|

Voltage/Frequency |

380v/220v-50Hz |

|

Hopper volume |

30L |

|

Dough ball weight |

25g-100g |

|

Production capacity |

2700-3000pcs/h |

|

Meast: |

150x85x150cm |

|

G.W/N.W: |

570/560kgs |

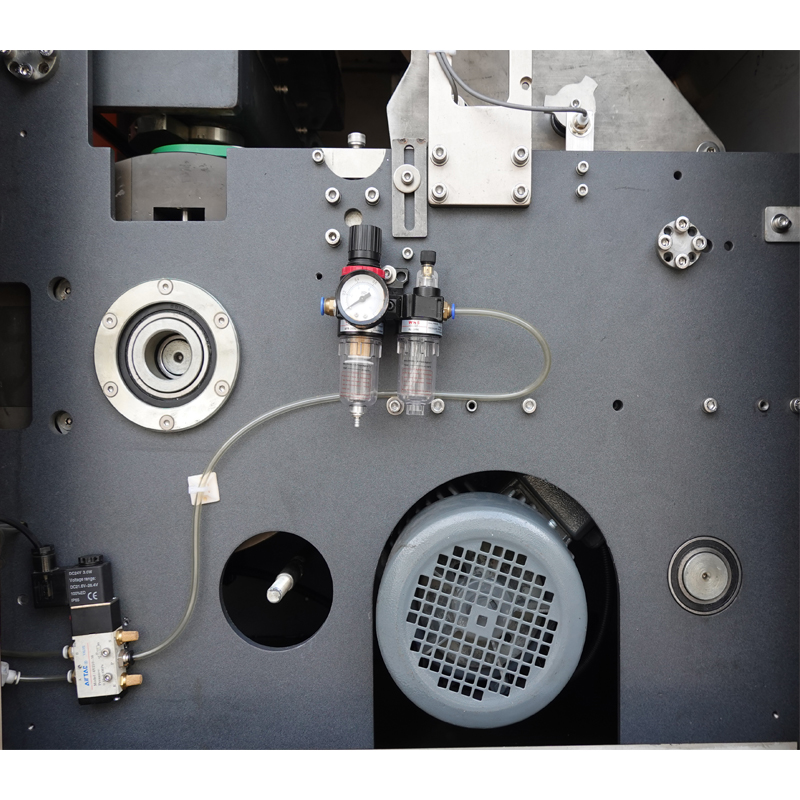

Operation board is simple,easy to operate.

It is easy to disassemble spare parts of hopper,convenient to clean and maintain.

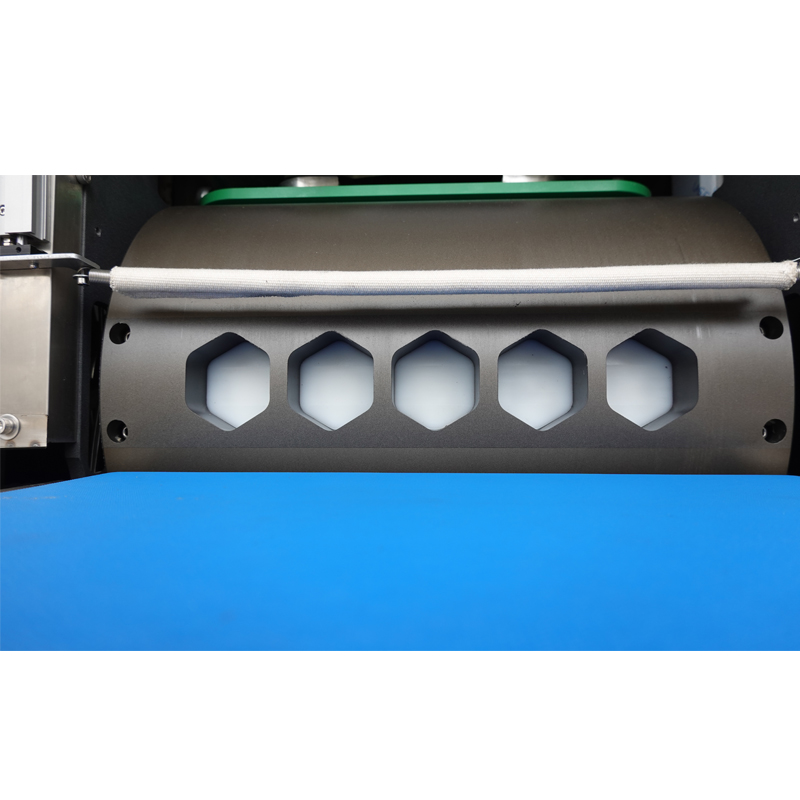

Special treatment to roller barrel,in high precision and wear-resistant,different mould for different product.There are 2sets of mould inside machine itself.

The dough balls come out in row and column.And it is convenient for the next step job.Uniform weight,tolerance within 1g for same batch.

Why Choose Yuyou?

1. Each machine is manufactured by experienced professional staff.

2. The production process is strictly monitored, and the Chinese and world-class production techniques are adopted.

3. The warranty period is one year. Does not include wearing parts.

4. After the expiration of the warranty period, a lifetime maintenance service will be provided.

Pre-sale service:

1. We provide various forms of pre-sale services, carrying out investment budget, manufacturing, and planning, so that customers can make reasonable plans at a lower cost.

2. We will first check the customer’s goods and the size of the goods, and then we will recommend a suitable packaging machine to be 100% suitable.

3. We will recommend and provide machines according to customers’ use and purchase budget.

In-sale service:

1. We will provide photos of each manufacturing step on time for customers to check.

2. We will prepare packaging and delivery in advance according to the needs of customers.

3. Test the machine and make videos for customers to check.

After-sales service:

1. We will guarantee the quality of the machine for 1 year.

2. We provide free training to answer customers’ technical questions in a timely manner.

Product detail pictures:

Related Product Guide:

The dough mixer is a top-of-the-line dough mixing machine designed for professional bakers and baking enthusiasts. It simplifies and streamlines the process of dough mixing by providing a powerful, user-friendly solution that saves time and effort. China wholesale Dough Cutter And Rounder - Dough Divider and Rounder YQ-605 – Yuyou , The product will supply to all over the world, such as: Niger, Danish, Jordan, Invest in our Dough Placing Machine for an efficient and reliable solution to your food production needs. Its automatic placement, high efficiency, cost-effectiveness, and durable construction make it an invaluable asset to any food processing facility.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!